Nominal production rate for every megawatt of capacity.

Specifications

| Inputs* |

|

|---|---|

| Outputs |

|

| Size** |

|

| Performance |

|

| Control |

|

(*) Low Voltage or Medium Voltage available upon requests.

(**) Customized footprints solutions available.

(***) 58kW/kg is the maximum power consumption inside the operating range of 10% to 100%.

| Inputs* |

|

|---|---|

| Outputs |

|

| Size** |

|

| Performance |

|

| Control |

|

(*) Low Voltage or Medium Voltage available upon requests.

(**) Customized footprints solutions available.

(***) 58kW/kg is the maximum power consumption inside the operating range of 10% to 100%.

| Inputs* |

|

|---|---|

| Outputs |

|

| Size** |

|

| Performance |

|

| Control |

|

(*) Low Voltage or Medium Voltage available upon requests.

(**) Customized footprints solutions available.

(***) 58kW/kg is the maximum power consumption inside the operating range of 10% to 100%.

| Inputs* |

|

|---|---|

| Outputs |

|

| Size** |

|

| Performance |

|

| Control |

|

(*) Low Voltage or Medium Voltage available upon requests.

(**) Customized footprints solutions available.

(***) 58kW/kg is the maximum power consumption inside the operating range of 10% to 100%.

| Inputs* |

|

|---|---|

| Outputs |

|

| Size** |

|

| Performance |

|

| Control |

|

(*) Low Voltage or Medium Voltage available upon requests.

(**) Customized footprints solutions available.

(***) 58kW/kg is the maximum power consumption inside the operating range of 10% to 100%.

Configuration and support

Configuration and support

As pioneers in PEM electrolyser and hydrogen storage solutions, IMI’s engineering team will partner with you each step of the way to seamlessly adopt green hydrogen. Our hands-on experience equips us to understand your needs, tailor optimal systems, and ensure integration with existing infrastructure. We’re here to guide you through the complex energy transition and deliver the right solutions to meet your production goals. Work with our engineers to make the switch to green hydrogen a success.

Matt

Project Engineer at UK based customer

Real-time wireless monitoring

Real-time wireless monitoring

The dashboard offers customisable, cloud-based, real-time monitoring of the electrolyser’s performance. System operators can monitor all key parameters, including hydrogen pressure and flow rate, stack and system efficiency, DC / AC power consumption, and cooling temperatures. The dashboard is available for PCs, Macs, tablets, and smartphones and can be used at any location with a Wi-Fi or mobile data internet connection.

Learn moreHydrogen storage solution

Hydrogen storage solution

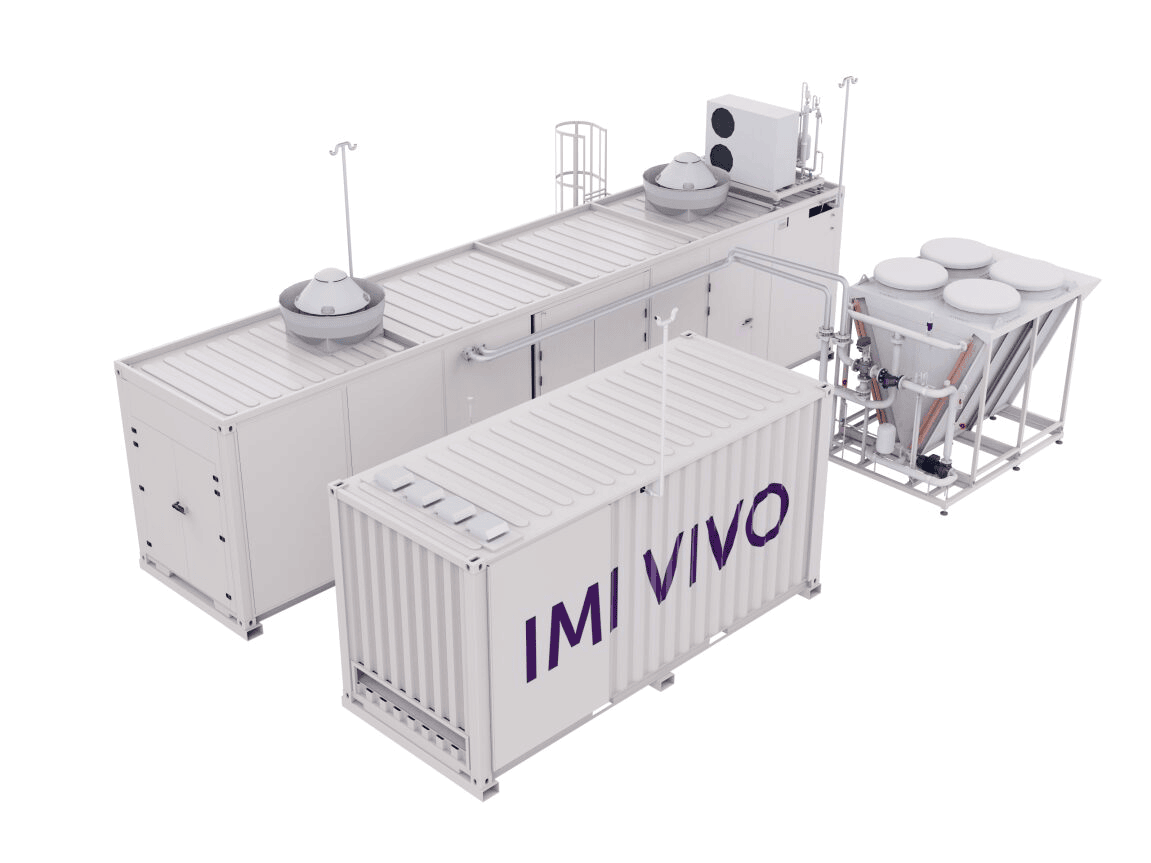

For efficient hydrogen storage, consider the IMI VIVO Type I Vessels. Designed to international codes like ASME or EN, they offer flexibility in size, capacity, and flange connections. Equipped with essential safety instrumentation, they operate at electrolyser discharge pressure up to 50barg, with options for higher pressures.

DiscoverSpec sheet download